Transforming and recycling the trety factory

A factory for living

The client, a company specializing in design, development and manufacturing of automobile interior components, began working with our studio in 1995 and continues working with us to 2005. These first projects were small transformations and interventions in an existing building, involving a 30,000 m2 complex. Over the years a renovation project has been developed for the building complex by: transforming the factory from the walls to the lavatories, including changing rooms and signage, thereby creating an authentic factory for “living.”

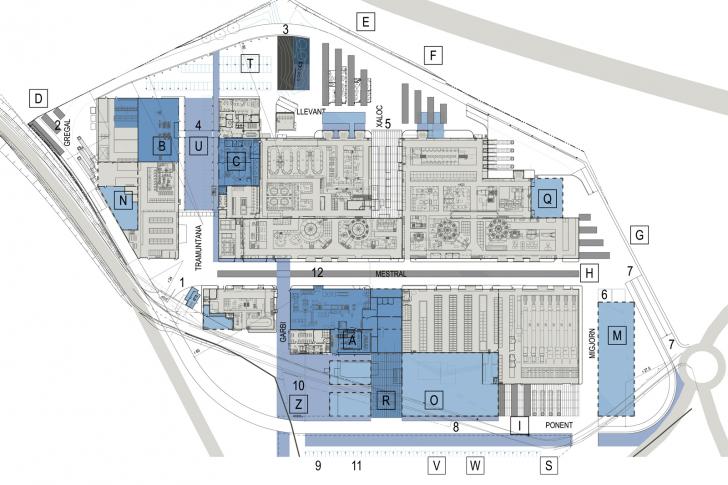

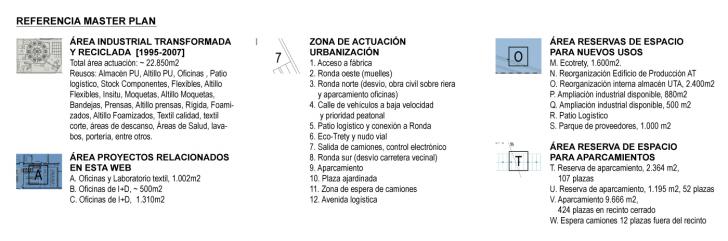

Interventions were carried out on these industrial building structures, that were buildings deprogrammed of their original functions; outdated production spaces, outsourced warehouses, maintenance workshops, in order to update them and give them new functions. The programme adapts to new requirements and is based on production spaces with new technology; staff break areas, logistic centres, loading and unloading facilities, reorganizing access routes and traffic, R&D offices, laboratories, health clinics and car parks.

Multiple interventions were carried out by sectioning and emptying existing buildings in order to construct reprogrammed spaces and uses.

Ficha técnica

[location] Maçanet de la Selva, Girona

[start date] 1995

[end date] 2007

[constructed area] 27.440 m2.

[surface plot] 60.000 m2

Team

[architect] Bogdanov Arquitectes

[installations] DB Asociados

[structure] BOMA

[furniture] Esmeralda Barea

[photography] Rafael Vargas

Customer

-

Trety

Leader Group in the manufacture and transformation of Textile and Plastics and all kinds of materials for the interior coating of vehicles.

-

Trèves Automotive

French Multinational Group, leader in the automotive seats and components, the interior trim and the acoustic and door panels of the vehicle.

The “Development Planning Round” is the last of forty projects and the culmination of ten years of working with this company. It is a Master Plan that unites the buildings and development planning among them; the access routes, loading bays, etc. This project consists of reorganizing exterior spaces and all the logistics, as well as managing sustainable waste treatment.

Trety multiplied their turnover and amount of employees by seven over the past ten years, just by increasing their professional space by 15%.