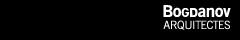

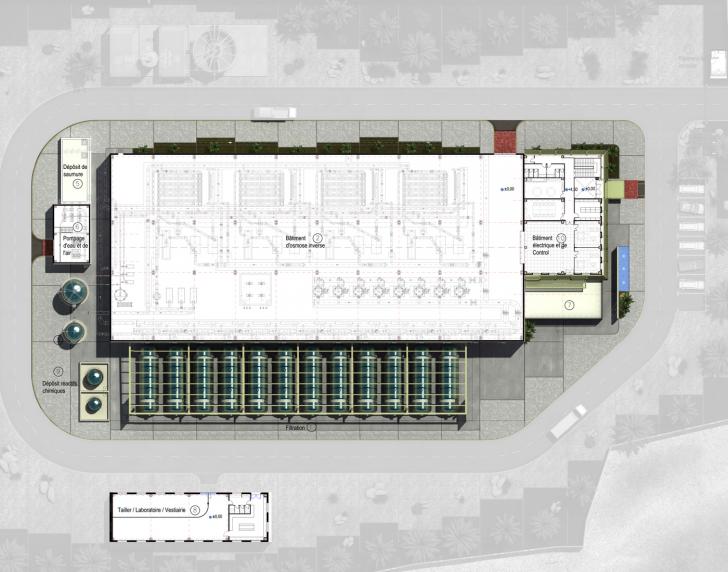

Masterplan desalination plant in Djerba, Tunisia

Design and integration with the surroundings of Djerba island (Tunisia)

The project consisted of a design integrated with the surroundings of Djerba island (Tunisia) of a reverse osmosis processing plant and neighbouring buildings.

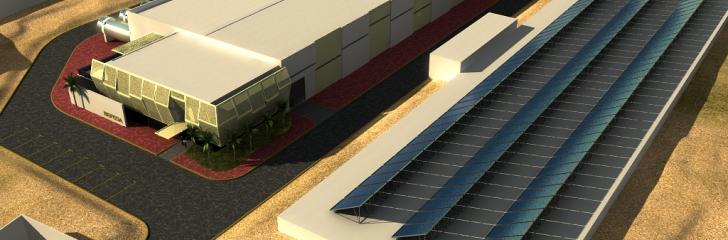

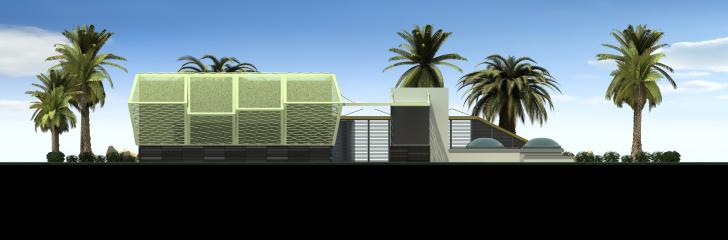

Project planning for this plant followed briefing agreed upon in meetings with technicians from Abengoa Water "applying a simple and efficient construction system in its entirety”. The load-bearing structure of the industrial plant was envisioned as metal and conventional. The plant had a simple metallic roof with an 8% slope mimicking the surroundings.

Ficha técnica

[location] Djerba, Túnez

[start date] 2009

[end date]

[surface buildings reverse osmosis] 4.883,40m2

[building surface seawater uptake] 680,25m2

[surface plot] 18.613m2

Customer

-

Abengoa Water

Abengoa Water is focused on promoting, developing and operating water-treatment plants, and especially on the desalination business.

The semi-enclosed section was able to minimize the contrast of an industrial building in an area that was residential and touristic with many hotels. The façade issue was resolved using a “double skin” technique (which brings to mind sand dunes). This double skin was created using latticing with perforated sheeting in different thicknesses that was folded at various distances regarding the brickwork enclosing wall, thereby contributing an efficient and natural cooling system inside the control room.

Expertise

The system was devised to be “workshop-manufactured” being collapsible and easy to transport to the island. The technological solution for the photovoltaic panels on top of the water tank was developed according to the supplier's proposal and the position was redesigned to improve visibility from outside. These environmental elements were painted bright blue, following the colour palette of local traditional architecture.

Team

[installations, civil works] Abengoa Water

[architect] Bogdanov Arquitectes & Sanzpont Arquitectura